There are a wide range of oil seals to select from for any number of uses, so this guide will break down the most common seals to help you choose the right one for whatever piece of machinery you are working on.

Although it does have a higher tensile strength and longer wear times than other materials, it is recommended to be used in dry-running applications sparingly or intermittently.

ERIKS type GV (type C according to DIN) is equivalent to type M, but is a heavy-duty version with a double metal casing. This can be a useful solution with larger diameters in more demanding applications. There is also a version of this type with a dust lip; the GVST (type CS according to DIN).

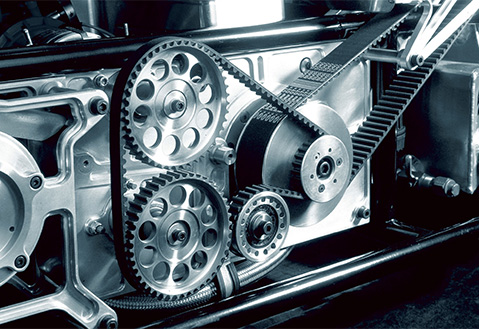

Types of oil seals

Oil leaks not only create messy stains on your engine but also attract dirt and debris, which can clog up other parts of your engine over time Oil leaks not only create messy stains on your engine but also attract dirt and debris, which can clog up other parts of your engine over time

Oil leaks not only create messy stains on your engine but also attract dirt and debris, which can clog up other parts of your engine over time Oil leaks not only create messy stains on your engine but also attract dirt and debris, which can clog up other parts of your engine over time valve cover gasket replacement. A well-maintained engine with properly functioning gaskets ensures that oil stays where it should be, reducing the risk of buildup and extending the lifespan of your engine.

valve cover gasket replacement. A well-maintained engine with properly functioning gaskets ensures that oil stays where it should be, reducing the risk of buildup and extending the lifespan of your engine. This makes it ideal for use in high-performance machinery and automotive systems where reliability is paramount This makes it ideal for use in high-performance machinery and automotive systems where reliability is paramount

This makes it ideal for use in high-performance machinery and automotive systems where reliability is paramount This makes it ideal for use in high-performance machinery and automotive systems where reliability is paramount oil seal 85x110x12.

oil seal 85x110x12.Heat and attrition are generated by the parts moving against each other. The sealing function can only be ensured if an intentional defined leakage of oil is able to exit for seal lubrication, preventing seal wear and possible failure, while a tight static seal between shaft and sealing lip must be assured when the shaft is stationary.

These oil seals are created from a low-temperature tolerant compound. Benefits include:

It is wedge-shaped to be pressed against the shaft surface and makes contact with the shaft to ensure sufficient sealing performance and suitability for operation at high peripheral speed.

Compounds for Automotive Power Train Systems

Mercedes-Benz

In conclusion, auto spark plugs, car spark plugs, and car iridium spark plugs are essential components in the ignition systems of vehicles, contributing to the efficiency, performance, and reliability of automotive engines. Understanding the significance of these components and their proper maintenance and replacement is crucial for optimizing the performance and longevity of the vehicle's ignition system.